Injector Coding Procedure Bosch Delphi Denso Siemens Guide

Injector Coding Procedure -Bosch, Delphi, Denso, Siemens

1. What is Injector Coding?

In modern Common Rail Diesel (CRD) systems, precision is everything. Even with high-precision manufacturing, no two fuel injectors are exactly identical. Minute differences in the nozzle needle or solenoid response time can lead to slight variations in the amount of fuel delivered.

Injector Coding (also known as IQA, IMA, or QR coding) is the process of programming a unique alphanumeric code into the engine’s Electronic Control Unit (ECU). This code acts as a "compensation factor." It tells the ECU exactly how much fuel that specific injector delivers so the ECU can adjust the injection timing and duration to balance the engine perfectly.

2. Why Coding is Required After Calibration

Why can't you just install a repaired injector and drive away?

When an injector is repaired or tested on a high-precision machine like the CR317S Common Rail Test Bench, its flow characteristics change. The old code stored in the ECU no longer matches the physical behavior of the injector.

Failure to perform the injector coding procedure results in:

Engine Knocking: Due to incorrect pre-injection timing.

Black Smoke: Caused by over-fueling.

Rough Idle: Because cylinder power balance is uneven.

Poor Fuel Economy: The ECU cannot optimize combustion.

3. Tools Required

To perform successful coding, you need two main categories of equipment:

Code Generation Tool: A test bench capable of running a full test plan and generating a new code (e.g., Bosch IMA or Denso QR) based on the flow data.

Recommended:CR317S Common Rail Test Bench

Code Input Tool: An OBDII Diagnostic Scanner (Scan Tool) capable of communicating with the vehicle's ECU to write the new codes. common brands include Launch, Autel

4. Step-by-Step Injector Coding

While menus vary by scanner, the general injector coding procedure follows these steps:

Identify the Injector: Note the code printed on the injector head or the new code generated by your test bench.

Connect Scanner: Plug your diagnostic tool into the vehicle's OBDII port.

Select Vehicle: Enter the Make, Model, and Engine type.

Access Special Functions: Navigate to Powertrain -> Adaptation or Special Functions -> Injector Coding (or Injector Correction).

Input Codes:

Select the Cylinder number (e.g., Cylinder 1).

Delete the old code.

Type in the new alphanumeric code carefully.

Confirmation: Save the data. The ECU may require the ignition to be cycled (Turn Key Off -> Wait 10s -> Turn Key On).

Verification: Read the codes back to ensure they were saved correctly.

5. Brand Differences: Bosch vs. Delphi vs. Denso vs. Siemens

Different manufacturers use different coding standards to manage flow rates and reaction times. Understanding these differences is vital, especially when dealing with Piezo technology.

Table: Injector Coding Standards Comparison

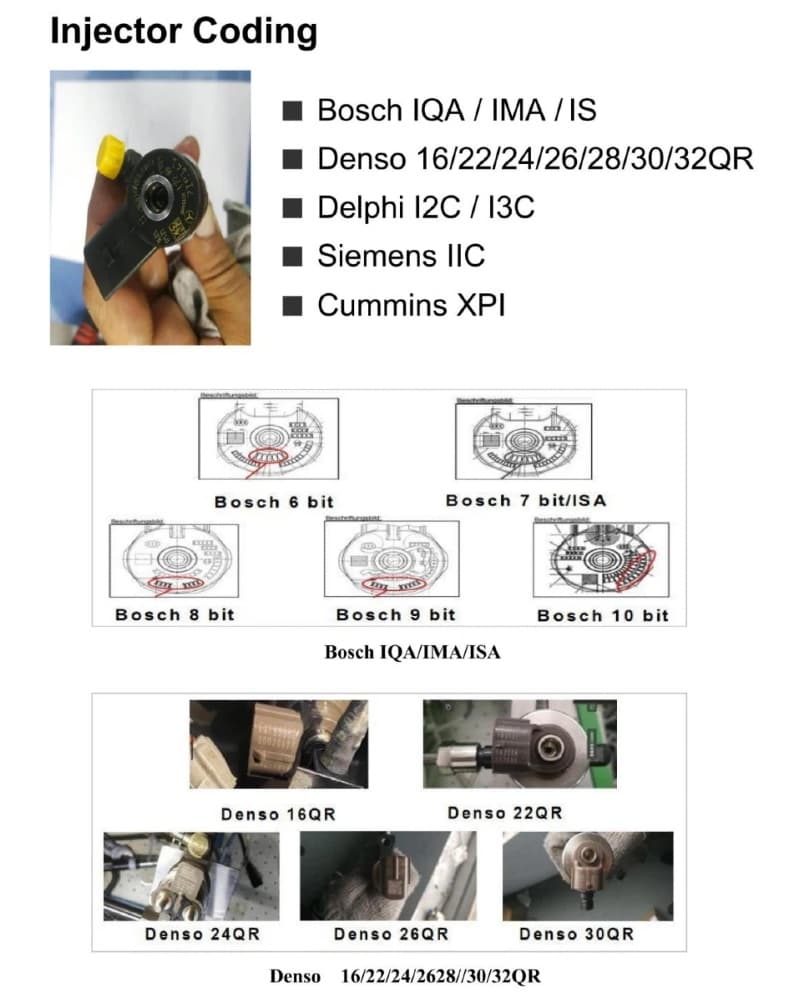

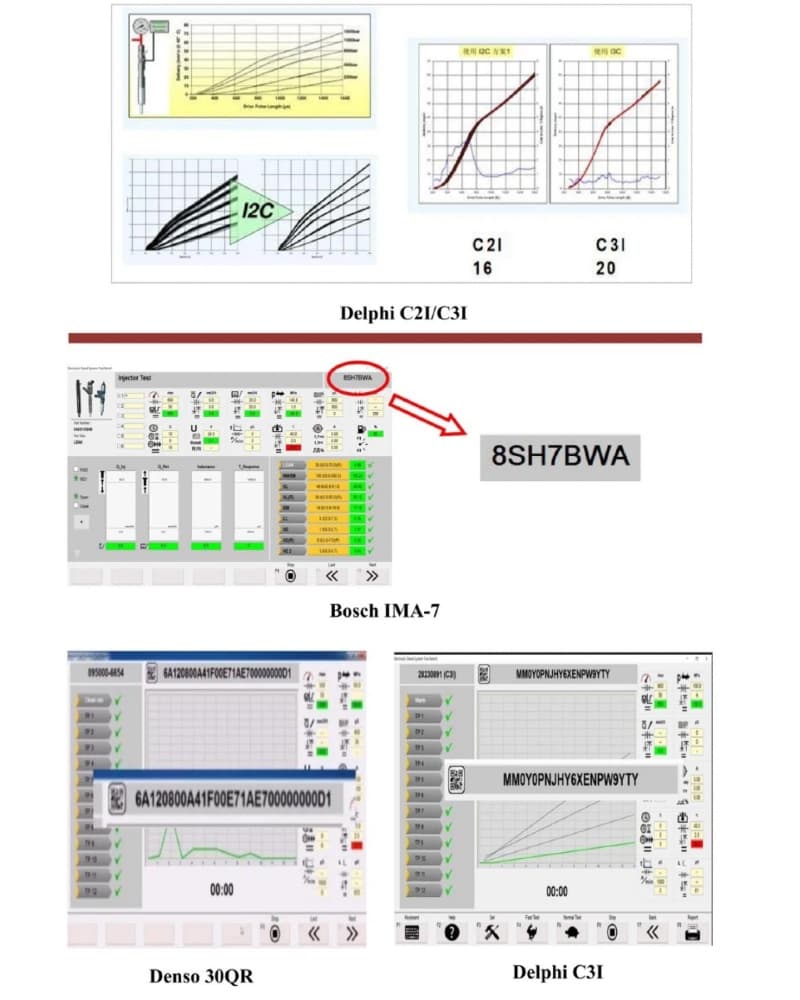

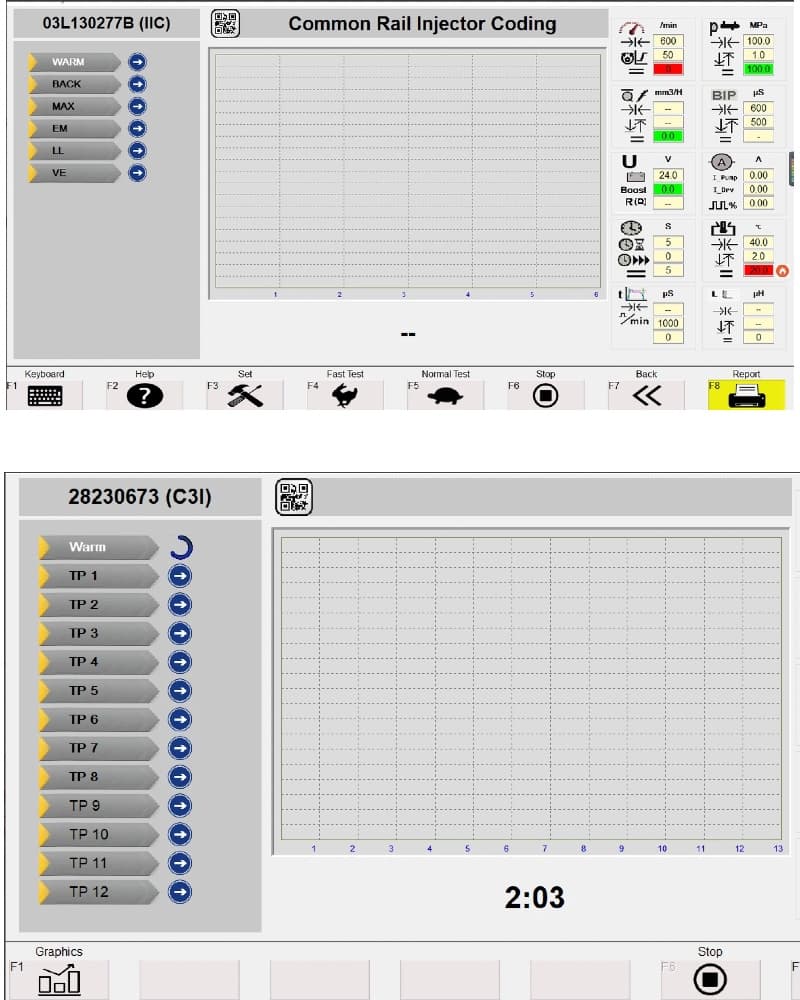

| Feature | Bosch | Delphi | Denso | Siemens (Continental/VDO) |

| Code Name | IMA / ISA | C2I / C3I | QR Code | IIC (Injector Individual Correction) |

| Format | 6 to 9 Digits (Alphanumeric) | 16 or 20 Digits (Hexadecimal) | Complex 2D Barcode / 16-30 Digits | 6 Digits (Alphanumeric) |

| Technology | Solenoid & Piezo | Solenoid (mostly) | Solenoid & Piezo | Piezo Only |

| Sensitivity | Moderate. Focuses on flow adjustment. | High. Includes precise timing data. | Very High. Compensates for multiple pressure points. | Critical. Calibrates the voltage profile for the Piezo crystal. |

| Common Issue | ECU rejects code if the wrong part number is used. | Very long codes often lead to typing errors. | Generic scanners often fail to read the complex QR format. | Piezo Sensitivity: Incorrect coding can cause immediate engine rattling or stalling. |

Specific Note on Siemens / Continental / VDO

Siemens injectors (now manufactured by Continental and often branded as VDO) predominantly use Piezoelectric technology. Unlike Solenoid injectors which rely on a magnetic coil, Piezo injectors use a crystal stack that expands when energized.

The "IIC" Code: The 6-digit code on a Siemens injector is critical because it tells the ECU the specific voltage and energy profile required to open that specific Piezo stack.

Warning: Because Piezo crystals are extremely sensitive to voltage, inputting the wrong code or swapping injectors without coding can cause the ECU to drive the injector with the wrong voltage, potentially damaging the injector or the ECU driver permanently.

6. Common Errors During Coding

Even experienced technicians make mistakes during the injector coding procedure. Watch out for these pitfalls:

Cylinder Numbering Confusion:

Some ECUs count cylinders physically (1-2-3-4).

Others follow the firing order (1-3-4-2).

Tip: Always refer to the vehicle service manual to identify Cylinder 1 location.

Typing Errors: Confusing the number "0" with the letter "O", or "1" with "I". Most coding systems use Hexadecimal (0-9, A-F), so letters like "O" or "I" are usually invalid.

Wrong Injector Class: If you install an injector with a different part number than the ECU expects, the ECU will reject the code immediately.

Skipping the Test Bench: Using a code printed on an old, worn injector is useless. You must generate a new code using a test bench if the injector has been repaired.

If you are experiencing issues where the injector passes the electrical test but fails to code or operate, check our guide on [How to Test Common Rail Injector] to ensure the mechanical components are sound.

Conclusion

Injector coding is the final, non-negotiable step in the diesel repair process. It bridges the gap between mechanical precision and electronic control. By using a quality test bench like the CR317S to generate accurate codes and following the correct input procedure, you ensure the engine runs smooth, clean, and efficient.

Related products

Language

Language